From large-scale commercial projects to everyday installs, Grove Shims are trusted on jobsites across the United States. Builders, glaziers, and contractors rely on our plastic shims for precision, strength, and consistency—because when the details matter, the right shim makes all the difference.

Explore real examples of Grove Shims in action, shared by the professionals who use them every day.

Global Security Window Installation.

Installing heavy-duty security windows across various environments with a need for consistent performance and long-term durability.

Grove shims are a standard part of every Harden Architectural Security installation. These shims are used to support and position high-security window systems to ensure stability and proper alignment.

Eco-Conscious Residential Construction.

Building a 5,000 sq. ft. off-the-grid home with fiber exterior panels that required perfect alignment and spacing for aesthetics and airflow.

Grove plastic shims were used in two critical ways:

1. To offset aluminum rails from the structure – allowing air flow expansion, and thermal performance.

2. To align fiber panels – delivering a visually flawless exterior and meeting strict design expectations.

Educational Facility Window Installation.

Ensuring precision and structural support for interior punched SF windows, with consistency across multiple window types.

M-TECH Glass used 3/8″ Grove Shims for interior window installations, helping to ensure proper spacing and secure alignment. Grove Shims are their go-to solution for all framing needs, including storefront systems, curtain walls, and standard windows.

Commercial and Residential Installations.

Achieving consistent alignment and clean finishes across windows, doors, and trim installations.

Solvay Glass uses Grove Shims as a critical tool on every job to level, square, and plumb various building elements—from windows and door frames to detailed trim work.

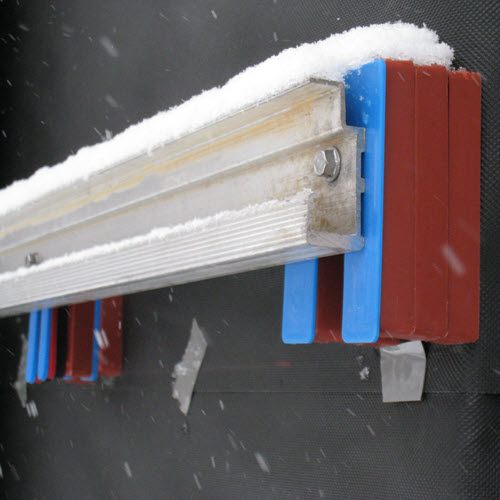

Panel System Installation.

Achieving a level substrate for panel installation by properly spacing and supporting hat track over a horizontal bar.

Grove U-shaped plastic shims were used to shim out the hat track, creating an even surface before securing the panels. This helped prevent misalignment and simplified the overall installation process.

Residential Window Installation.

Providing stable, reliable support for window units during installation in rough openings on residential job sites.

Baywest Projects uses Grove Shims in the rough openings to support the load of the installed windows. The shims help create a solid base that maintains window position and structural integrity throughout the install process.

Rugged, inexpensive, and convenient leveling and alignment aids for the glass and construction industry. Take a look at our selection of solid plastic shims. Custom plastic shim manufacturing is available as well.