Grove Shims will be closed June 24–July 6. No shipping or manufacturing during this time. |

Thousands of solid plastic shims are typically used during the course of a construction job. They are employed as temporary alignment aids to keep things in place until they can be connected, as well as long-term solutions for maintaining spacing between joints. Because of their tiny size and secondary function, designers and specifiers frequently overlook them. However, a plastic shim is an integral component of the process no matter if permanent or temporary, especially in high-detailed systems and environments where a fast pace is required.

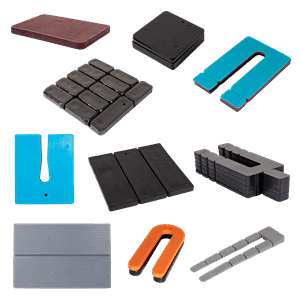

Solid plastic shims are a more convenient solution than wood and steel shims for construction jobs because they do not rot, rust, or deform. They also don’t require significant configuring because they are often available in a variety of widths and designs that can be trimmed to size easily. However, not all plastic shims are created equal, and it is important to pay attention to the different features during the selection process.

Some plastic shims are manufactured hollow, and some are solid. When choosing shims based on compressive strength and durability, plastic solid shims offer advantages over hollow shims. You can always count on Grove Shims for high-impact solid plastic shims.

Some companies provide wedges with shims notched at convenient lengths and depths, such 6- and 8-inch wedges with notches cut at predetermined intervals. Others make solid plastic shims that are typically uniform in thickness and are often color-coded, making installation and inspection in the field easier. And, some plastic shim manufacturers such as Grove offers both options.

Standard sizes can be combined to fit almost any size joint and are often stackable. Plastic shims may be linked together or, in certain situations, heat-sealed at the seams. All of these benefits add up to a significant labor time savings during the construction process.

In simple projects, flat plastic shims can be utilized to fill gaps that will later be filled with grout or sealant. Shims that are U-shaped can be utilized as permanent spacers in precast concrete wall cladding as well as curtain wall systems. Beyond the shape, the right shim style depends on the project requirements such as compressive strength, heat exchange, chemical resistance and more.

Who Will Set the Requirements

At times, architects and design professionals may delegate much of shim selection to the contractor’s suppliers and installers if a project is specified and completed. In this case, how well a shim performs will be the ultimate responsibility of the contractor if the prints and specifications are sufficiently detailed.

When designers create engineered systems that require tight control over other materials within the building system, they should not forget to include shims. For example, when a delicate stone is selected for wall cladding, designers must describe the support mechanism for that stone, including any shims. Designers must specify the shim in any instance where shims are used to deliver function, such as fire resistance or thermal transfer reduction.

What Aspects May Be Specified

While an integral part of any system, shims may not be specified by design or shape. However, the material composition of the shim may be specified. For example, when used in an area of the building designated as solid plastic shims may be required.

Other material characteristics that may be addressed include durability, flexibility, and fire resistance. Shims can also have other properties such as compliance and resilience. Results-oriented specs are required for shims in many cases. Examples of this include specifications like “Shims should not be visible for longer than 24 hours” or “Do not shim cladding more than a half-inch thick without a written agreement from the engineer.”

Plastic shims can be used in a variety of ways, from simple, temporary applications to roles within specialty cladding systems. They may be chosen depending on their features to speed up installation and improve building performance. Even small building elements such as shims can have a big impact on the project’s success and bottom line.

Solid plastic shims from Grove Shims are constructed of high-quality polypropylene, polystyrene, and ABS in a range of shapes and styles. There’s one to perfectly match your construction or industrial needs. For help selecting and purchasing heavy-duty plastic shims for your business, contact our experts today.

For help selecting and purchasing heavy-duty plastic shims for your business, contact us.